Pump technology

- Pump viscosity correction

- Impeller cuts

- How to change the pump performance

- Centrifugal pump introduction

- Cavitation

- Right impeller selection

- Pump installation

- Vertical turbine pump

- Tops for specifying pumps

- Determine between end suction pump and double suction pump

- Understanding the NPSH

- Axially split case pump

Pump category

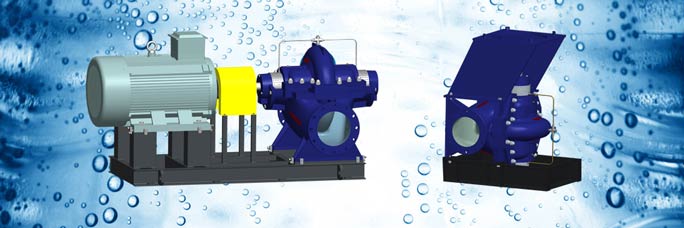

Axially split case pump

What is axially split case pump?

It is a type of centrifugal pump with the volute casing that is split by a plan through / parallel with the shaft centerline. The rotor is supported between bearings. Usually the suction nozzle and discharge nozzle is on the same centerline and arranged in the opposed position. Hankia always design the both the suction and discharge connection with the same pressure class.

Horizontal split case and vertical split case

For the axially split case pump, if the shaft centerline is horizontal, it is know as the horizontal split case pump, usually coupled with IM B3 type motor through the flexible coupling, with diesel engine through coupling on the SAE fly wheel, or gearbox. If the shaft is upright, it is know as the vertical split case pump. The horizontal split case pump is the most common type due the easy installation and maintenance.

Single stage split case and multistage split case

The single stage split case pump always has the double suction impeller that balances the axially hydraulic thrust to the impeller. If there is more than one impeller, it is known as multistage split case pump that usually has the first impeller as the double suction impeller, other impellers are side suction or double suction depending on the balance of the axial hydraulic thrust.

Advantage of axially split case pump

1. Excellent hydraulic performance.

Stable performance, high efficiency are the significant advantages as compared with the radially split case pump, eg. end suction pump.

2. Easy maintenance.

Because the volute case is axially split, you only need to remove the upper casing to check the pump and replace the worn parts, eg. impeller, wear rings, shaft sleeve,

3. Fast replacing the shaft sealing.

To replace the soft packing, you only need to loose the packing gland and insert the new soft packing. To the replace the mechanical seal, you only need to take off the bearing and loose the mechanical seal cover joints, then replace the new mechanical seal, it is not necessary to dismantle and pump casing cover. The between bearing construction allow it to have this advantage.

You can also visit the column "Axially split case pump" on our Official Blog.