Split case pump

Pump category

Pump selection tips

Hankia pump have the horizontal split case pump and vertical split case pump for your options. Usually the horizontal split case pump is prior to vertical split case pump because the horizontal split case is easier to install and maintenance as compared with veritcal split case pump.

For the same project, if both the end suction pump and split case pump can meet the service, split case pump usually need more budget although it has longer life time. So you can consider the split case pump as the secondary option if it is not critical project.Because of the unique feature of split case pump, the split case pump is usually preferred to the main pumps or critical projects.

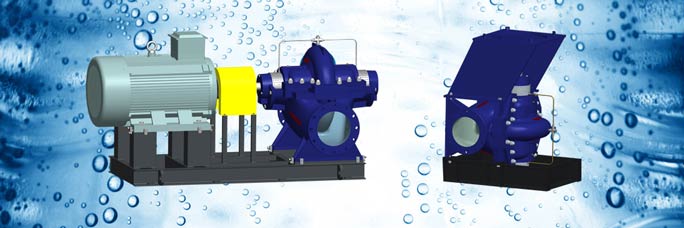

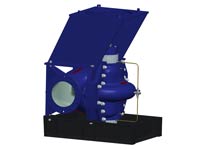

DS(V) type axially split case double suction pump

DS(V) type is the axially split case pump, single stage, double suction pump. DS is the horizontal single stage split case pump and DSV is the vertical single stage split case pump. The DS type horizontal split case pump and veritical DSV type split case pump have the same performance. DS(V) split case pump is pump featured with high efficency and reliable performance. Due to the excellent performance and high quality from Hankia Pump, the pumps are widely selected by the users all over the world for their primary liquid pumping equipment in their projects.

DS(V) type is the axially split case pump, single stage, double suction pump. DS is the horizontal single stage split case pump and DSV is the vertical single stage split case pump. The DS type horizontal split case pump and veritical DSV type split case pump have the same performance. DS(V) split case pump is pump featured with high efficency and reliable performance. Due to the excellent performance and high quality from Hankia Pump, the pumps are widely selected by the users all over the world for their primary liquid pumping equipment in their projects.

However, Hankia Pump is always making the innovation of the NPSHr and efficiency and expanding the performance range of DS(V) split case pump in order to meet the clients' more application requirements. DS(V) is the ideal split case pump for your projects.

Main designing features

- Double volute design for pumps with single head over 60m, compeletely balance the radial force and ensure reliable service and save your maintenace costs.

- Horizontal and vertical construction allow your flexible installation request.

- Foot support and centerline support is optional for your flexible application.

- Optional rotation for clockwise (CW) and anti-clockwise (CCW).

- Optional shaft sealing for single seal mecanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Optional stuffing box cooled by third coolant, bearing bracket with cooling jacket or finned shape to allow the pump to transfer your very hot liquid.

- Normally the suction and discharge nozzle is horizontal at the same centerline. Hankia Pump can also supply suction nozzle is down or vertical, discharge nozzle vertical to fit your pipleline arrangement.

- Bearing lubrication is optional for grease or oil. Sleeve bearing is also possible.

- Optional bearing temprature and vibration trubes allow you to know the working of the pump.

Main benefits

- Double suction impeller with optimum hydraulics optimized by CFD analysis and the fluid experts from Hankia Pump

- 3D design to ensure nice performance and excellent construction.

- Low NPSHr and high efficiency at wide performance range.

- Many choices for material, cast iron, cast steel, all stainless steel and duplex stainless steel, bronze for your different application.

- Wind performance range allow you to have a reasonable project design in Hankia Pump's DS(V)

- Excellent pumps with fast delivery.

- Compacted design allow you save your landing space.

- Long lifetime and easy mentenance.

Main application

- Water lift and transporation in water plant and municipal projects.

- Agricultural Irrigation.

- Power station and nuclear power station

- Offshore Projects and sea water.

- Air-conditioning and heating.

- Mining and steel plants.

- Fire fighting.

- Water circation.

Basic service data

- Capacityup to 7000L/s (25200m3h), if you need special performance,Hankia Pump can offer tailor made pumps for your application

- Headup to 280m(920ft), if you need special performance,we can offer tailor made pumps for your application

- Working temperatureup to 160°C, the declaration should be cleared before the project inquiry if the temperature >80°C

- Design pressure1.0Mpat /1.6Mpa / 2.5Mpa /3.0Mpa which depends on the application.

- Nozzleup to 1400mm or tailor design. Flange standard can be DIN, ANSI or other standard.

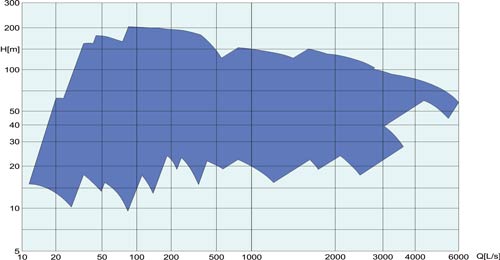

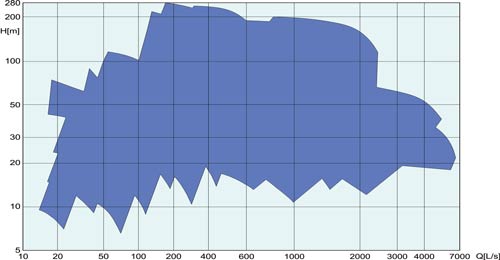

Performance range

Performance range at 50Hz

Performance range at 60Hz