Pump technology

- Pump viscosity correction

- Impeller cuts

- How to change the pump performance

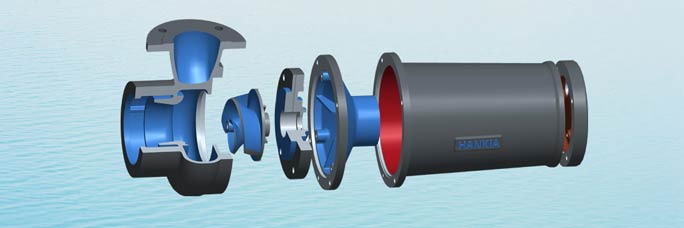

- Centrifugal pump introduction

- Cavitation

- Right impeller selection

- Pump installation

- Vertical turbine pump

- Tops for specifying pumps

- Determine between end suction pump and double suction pump

- Understanding the NPSH

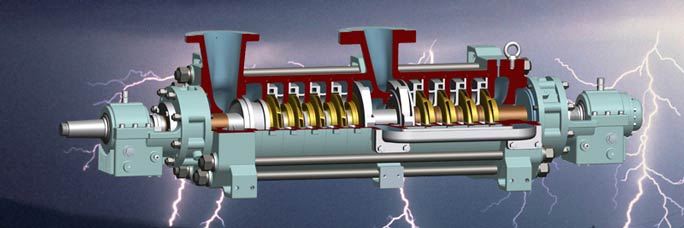

- Axially split case pump

Pump category

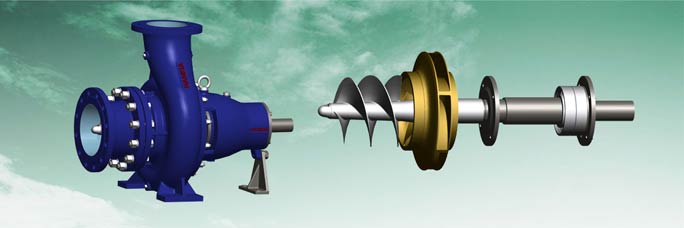

Right impeller selection

There are multiple decisions to be made about the impeller selection and not all pump suppliers are qualified to make them: The impeller shape or specific speed number will dictate the shape of the pump curve, the NPSH required and influence the efficiency of the pump.

Has the impeller configuration been in recent years? Impeller design is improving with some of the newer computer programs that have become available to the design engineer.

The suction specific speed number of the impeller will often predict if you are going to experience a cavitation problem.

The impeller material must be chosen for both chemical compatibility and wear resistance. You should consider one of the duplex metals because most corrosion resistant materials are too soft for the demands of a pump impeller.

The decision to use a closed impeller, open impeller, semi-open, or vortex design is another decision to be made.

Closed impellers require wear rings and these wear rings present another maintenance problem.

Open and semi-open impellers are less likely to clog, but need manual adjustment to the volute or back-plate to get the proper impeller setting and prevent internal recirculation.

Vortex pump impellers are great for solids and "stringy" materials but they are up to 50% less efficient than conventional designs.

Investment cast impellers are usually superior to sand cast versions because you can cast compound curves with the investment casting process. The compound curve allows the impeller to pump abrasive fluids with less vane wear.

If you are going to pump low specific gravity fluids with an open impeller, a non-sparking type metal may be needed to prevent a fire or explosion. You will be better off choosing a closed impeller design with soft wear rings in these applications.

The affinity laws will predict the affect of changing the impeller speed or diameter. You will want to be familiar with these laws for both centrifugal and PD pumps.

Hankia pump suggested that it is very important to slecet the right impeller type. It will affect the pump liftime, your project budget, maintenance cost, system efficiency, operation cost and energy saving, etc.. If you are sure of what types of impeller shall be used, it is good idea to contact our fluid experts and tell us the site condition and liquid properties. Hankia's experts will offer the reasonable proposal to you.