Pump technology

- Pump viscosity correction

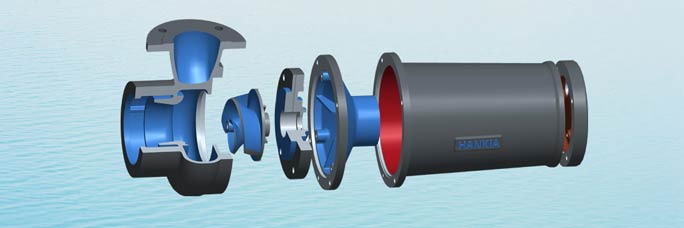

- Impeller cuts

- How to change the pump performance

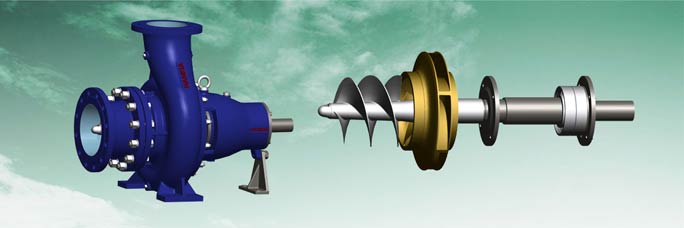

- Centrifugal pump introduction

- Cavitation

- Right impeller selection

- Pump installation

- Vertical turbine pump

- Tops for specifying pumps

- Determine between end suction pump and double suction pump

- Understanding the NPSH

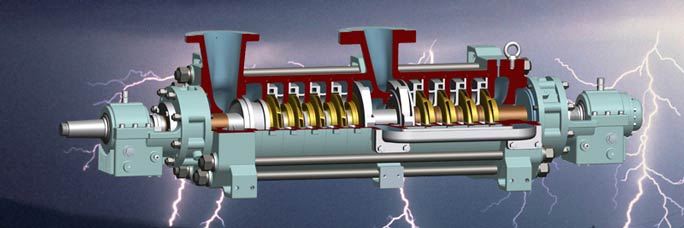

- Axially split case pump

Pump category

Impeller cuts

Assuming that the impeller represents a standard design, say specific speed below 2,500, and that the impeller profile is typically of average layout and not specifically designed for high NPSH, the pump performance with trimmed impellers will generally follow the affinity laws as long as some vane overlap is maintained.

The affinity laws express the mathematical relationship between the several variables involved in pump performance. They apply to all types of centrifugal and axial flow pumps. They are as follows:

1. With impeller diameter, D, held constant:

Q2 = (Q1) (N2/N1)

H2 = (H1) (N2/N1)2

BHP2 = (BHP1) (N2/N1)3

where:

Q = Capacity

H = Total Head

BHP = Brake Horsepower

N = Pump Speed, rpm

2. With speed, N, held constant:

Q2 = (Q1) (D2/D1)

H2 = (H1) (D2/D1)2

BHP2 = (BHP1) (D2/D1)3

When the performance (Q1, H1 & BHP1) is known at some particular speed (N1) or diameter (D1), the formulas can be used to estimate the performance (Q2, H2, & BHP2) at some other speed (N2) or diameter (D2). The efficiency remains nearly constant for speed changes and for small changes (up to 5%) in impeller diameter. To compensate for hydraulic mismatch and mechanical imperfections, correction factors are normally applied to the impeller cuts. The efficiency of the cut impellers (within a 25% cut) will usually drop about two points at the maximum cut. On high Ns pumps, the performance of the cut impellers should be determined by shop tests or vendor curves

EXAMPLE

To illustrate the use of these laws, assume that you have performance data for a particular pump at 1,750 rpm with various impeller diameters. The performance data have been determined by actual tests by the manufacturer. Now assume that you have a 13” maximum diameter impeller, but you want to belt drive the pump at 2,000 rpm. The affinity laws listed above will be used to determine the new performance, with N1 = 1,750 rpm and N2 = 2,000 rpm. The first step is to read the capacity, head, and horsepower at several points on the 13” diameter curve. For example, one point may be near the best efficiency point where the capacity is 300 gpm, the head is 160 ft, and the horsepower is approximately 20 hp. According to the affinity laws at N = 2,000 rpm, the new capacity is 343 gpm, the new head is 209 ft., and the new horsepower is 30 hp.

Q2 = (300)(2,000/1,750)

Q2 = 343 gpm

H2 = (160)(2,000/1,750)2

H2 = 209 ft.

BHP2 = (20)(2,000/1,750)3

BHP2 = 30 hp

Cutting impeller is the valuable method to utilize the current standard pumps. Hankia had huge testing database of the performance of its pumps after the impeller being cutted. So we can supply the pumps that exactly reach your project design data.