Pump technology

- Pump viscosity correction

- Impeller cuts

- How to change the pump performance

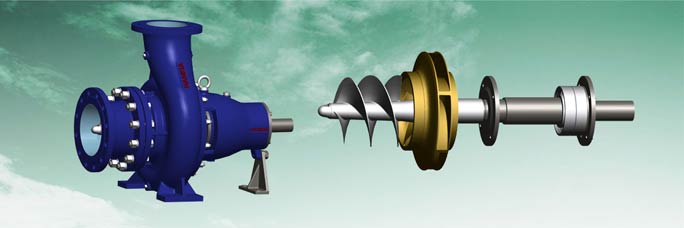

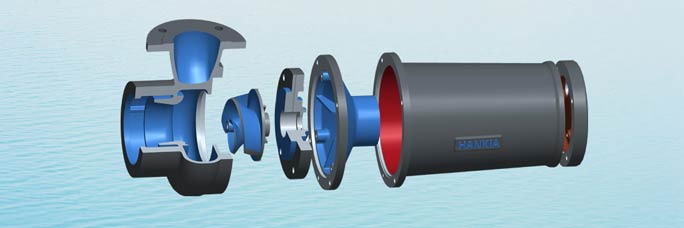

- Centrifugal pump introduction

- Cavitation

- Right impeller selection

- Pump installation

- Vertical turbine pump

- Tops for specifying pumps

- Determine between end suction pump and double suction pump

- Understanding the NPSH

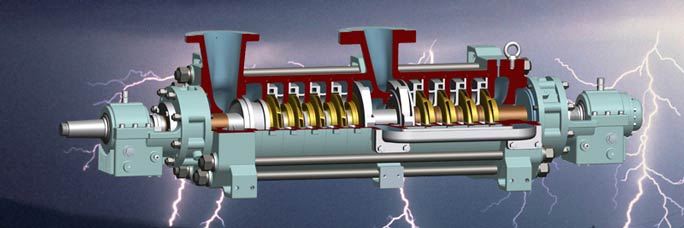

- Axially split case pump

Pump category

Understanding the NPSH

In a hydraulic circuit, net positive suction head (NPSH) may refer to one of two quantities in the analysis of cavitation:

1.The Available NPSH (NPSHA): a measure of how close the fluid at a given point is to boiling, and so to cavitation. The NPSHA is a function of the system design involving only four factors, all of which are in the control of the plant personnel.

2.The Required NPSH (NPSHR): the head value at a specific point (e.g. the inlet of a pump) required to keep the fluid from cavitating. The NPSHR is a function of the pump design, and changing it should involve the pump design engineers.

NPSH is particularly relevant inside pumps and turbines, which are parts of a hydraulic system that are most vulnerable to cavitation. If cavitation occurs, the drag coefficient of the impeller vanes will increase drastically - possibly stopping flow altogether - and prolonged exposure will damage the impeller

To avoid Cavitation: NPSH Available (NPSHa) > NPSH Required (NPSHr)

NPSHa = Hs + Ha - Hvp - Hf

where:

Hs = the static head above the centerline of the impeller

Ha = the pressure on the free surface of the liquid in the suction tank

Hvp = the vapor pressure of the liquid

Hf = all the friction losses on the pump inlet side

It is therefore apparent that, if a pump is cavitating, we should strive to increase the first two factors in the equation, and/or decrease the second two factors.

Static Head (Hs)

To increase the static head available to the pump is a simple (?) matter of lowering the pump, or raising the suction tank, or the level in the tank. The physical movement of the tank or pump would usually be a costly proposition, yet the raising of the tank levels may be relatively cheap and simple, and can frequently cure the problem.

Surface Pressure (Ha)

The surface pressure can be a little tricky to change if the suction source is the Atlantic Ocean or some other body of water that resists control by mere mortals. It might be possible however to enclose a man-made tank and pressurize it, or even introduce a nitrogen blanket. Both of these possibilities are subject to the dictates of the operating system. For example, increasing the pressure inside a deaerator would defeat the whole function of that vessel and must therefore be considered impractical. However, as pressure is one of only four factors in NPSHA formula, it is worthy of some consideration in certain installations.

Vapor Head (Hvp)

The only way to reduce the vapor pressure of a liquid is to reduce its temperature. Under many operational conditions this will be unacceptable and can be ignored. Also, the extent of the temperature change needed to provide an appreciable difference in NPSHA will render this method inappropriate.

Friction Losses (Hf)

As pump inlet piping is notoriously bad in the vast majority of installations throughout the world, this is the area where significant improvements can often be realized. However, I must caution you against the tendency to shorten the length of suction piping simply to reduce friction losses. While this will be effective, it could deny the liquid the opportunity of a smooth flow path to the eye of the impeller. This, in turn, could cause turbulence and result in air entrainment difficulties that create the same symptoms as cavitation. To avoid this, the pump should be provided with a straight run of suction line in a length equivalent to 5 - 10 times the diameter of the pipe. The smaller multiplier should be used on the larger pipe diameters and vice versa.

The most effective way of reducing the friction losses on the suction side is to increase the size of the line. For example, friction losses can be reduced by more than 50% by replacing a 12 inch line with a 14 inch line. Exchanging a 6 inch line for an 8 inch line can reduce the friction losses by as much as 75%. Reduction in friction losses can be achieved even with the same line size by incorporating long sweep elbows, changing valve types and reducing their number. Be careful of Suction Strainers that are left over from the commissioning stage of a new plant. The blockage in the strainer basket steadily raises the friction loss to an unacceptable level. To avoid this problem, a strainer can be frequently located downstream of the pump and the pump selected to handle the solid sizes expected.

Asking the right questions and rooting out the answers will ensure that you get the right pump on your first try. If you need more professional pump technology support and pump technology consult, please contact the International Trading and Cooperation Center (ITCC) for help.

NPSH curve

Hankia Pump usually establish the pump NPSH curve by testing its pumps at the testing working shop at the ambient condition. If the installation condition is not same as our testing ambient condition, the NPSH value will be corrected according to our application practice.