Pump technology

- Pump viscosity correction

- Impeller cuts

- How to change the pump performance

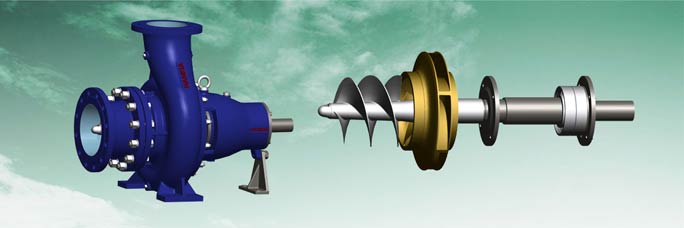

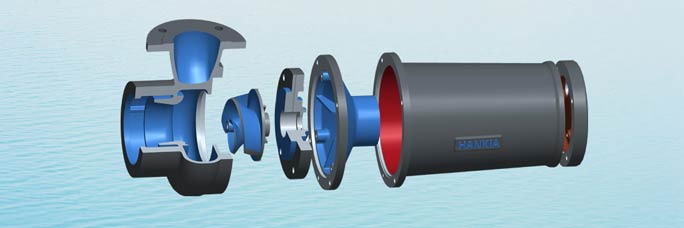

- Centrifugal pump introduction

- Cavitation

- Right impeller selection

- Pump installation

- Vertical turbine pump

- Tops for specifying pumps

- Determine between end suction pump and double suction pump

- Understanding the NPSH

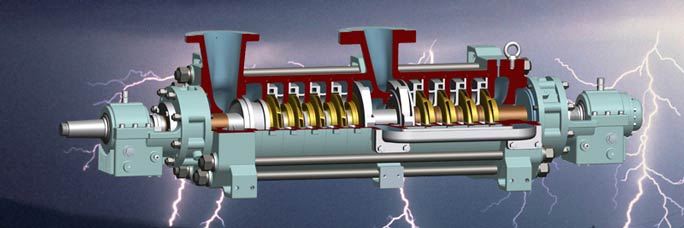

- Axially split case pump

Pump category

Pump installation

ome one has to install the pump and all of its associated hardware. The quality of this pump and driver installation will have a major affect on the performance and reliability of the pump, especially if it’s equipped with a mechanical seal.

he pump will be installed on a baseplate. The baseplate will be attached to a foundation and grout will be placed between the baseplate and the foundation to transmit any vibrations from the pump to the foundation.

Once the pump and driver are firmly on the foundation It'll be time to connect the piping. Be sure to pipe from the pump to the pipe rack and not the other way, so as to avoid pipe strain that will interfere with the operation of the mechanical seal and bearings.

There are many piping recommendations that you should be familiar with. The leveling, and pump to driver alignment can be made at this point, but you should check the alignment after the pump has come up to its operating temperature because metal parts expand and contract with a change in temperature.

If this is a new piping system some people like to install packing in the pump and run on packing until the new piping has been cleaned of slag or any junk that might be left in the piping system. If It's not a new installation, and there is a mechanical seal in the stuffing box, then installing the mechanical seal environmental controls will come next.

If the pump has an open or semi-open impeller It's time to make the initial impeller clearance setting. The final clearance can be set when the pump comes up to its operating temperature. It's important to note that if you do not have a cartridge seal installed in the pump the seal face loading will change as you make both the initial and subsequent impeller settings and there is nothing you can do about it.

You'll now want to do a proper venting of the pump. If It's a vertical installation you'll have to pay particular attention to keeping air vented from the stuffing box while the pump is running and be sure to vent the space between dual seals if they have been installed.

After you've done all of the above, It's time to check out the mechanical seal environmental controls to be sure they are working properly. In most cases the environmental control will continue to run after the pump has stopped. Be sure the operators understand this or they might be tempted to shut the control off when the pump is between batches. Seal quench is always a problem with operators because the steam or water dripping out of the seal gland looks like the seal is leaking.

A constant monitoring of the pump is a good idea. Are you familiar with some of the more popular monitoring methods? Unlike vibration analysis, monitoring can tell you if some part of the pump is getting into trouble before the vibration starts.

According to the Hankia Pump's pump application practice, a considerably partial of troubles and failure are caused by the unreasonable installation, for example, non-coaxial between the pump and diver center. The right installation will absolutely ensure the perfect working of the pump, prolong the pump lift span, reduce the maintenace cost and avoid unpredicated troubles. You can refer to our operation guide to install the pump or inquiry Hankia Pump for experience and instruction.