API610 / ISO13709 pump

- DSP type axially split case double suction pump

- MDS type multistage axially split case pump

- HMC type horizontal multistage ring section high pressure pump

- HMD type barrel (double) case high pressure pump

- CA type end suction petroleum chemical pump

- CO type end suction petroleum chemical pump

- CC type end suction petroleum chemical pump

- SP type chemical self-priming pump

Pump category

Pump selection tips

All pumps listed in this section are designed in compliance with API610 and ISO13709 standard that are mainly used as petroleum chemical pump for chemical process, water feeding, petroluem (oil) transferring and so on.

DSP (BB1 type) single stage split case pump and MDS (BB3) multistage split case pump are mainly used for petroluem (oil) transferring, loading, lifting. They are ideal main pumps for your chemical and petroleum projects on land or offshore.

HMC (BB4) mulistage ring section is usally used as high pressure water feeding pumps or boiling water pump.

HMD (BB5) is the barrel case pump (called as double case pump in API610) that is used for extra high pressure pumps.

There are three types of end suction pump in complance with API610 and ISO13709 mainly for chemical process pumps. Those pumps are CA OH1 petroleum chemical pump, CC OH2 petroleum chemical pump and CO petroleum chemical pump. CO type with open or semi-open impeller can be OH1 and OH2 construction.

For the chemical controlling or automatic process, we have SP type self-priming chemical pump in compliance with ISO5199 and API610.

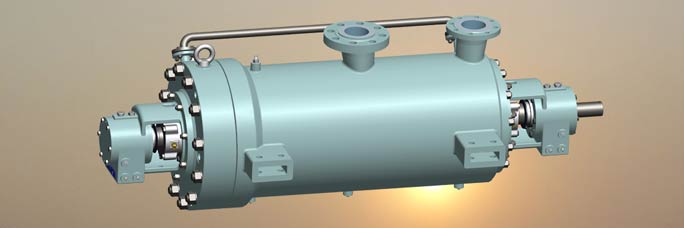

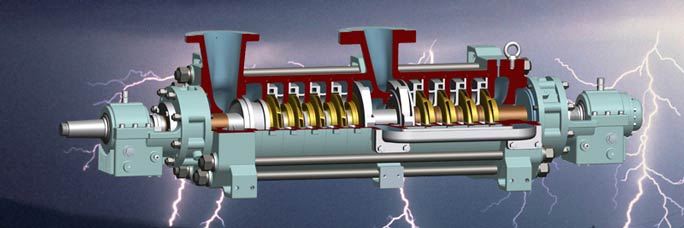

HMD type barrel (double) case high pressure pump

HMD type, the horizontal barrel case pump (called as double case pump in API610) as the extra high pressure pump, is fully compliant to API610 10th and ISO13709, BB5 type. Only the high pressure class barrel casing and nozzle expose to full pressure of the pump, therefor the total working pressure can much bigger. The rotor assembly can be pulled out by dismantling the end barrel casing cover. HMD (BB5) barrel case pump is the ideal extra high pressure pumps for high pressure water feeding, system boosting, boiling water, extra long distance oil transferring, and so on.

HMD type, the horizontal barrel case pump (called as double case pump in API610) as the extra high pressure pump, is fully compliant to API610 10th and ISO13709, BB5 type. Only the high pressure class barrel casing and nozzle expose to full pressure of the pump, therefor the total working pressure can much bigger. The rotor assembly can be pulled out by dismantling the end barrel casing cover. HMD (BB5) barrel case pump is the ideal extra high pressure pumps for high pressure water feeding, system boosting, boiling water, extra long distance oil transferring, and so on.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Ultra high pressure design barrel casing and nozzle can suffer extrimely high total working pressure.

- The rotor assembly can be pull out by dismantling the barrel casing cover, easy to do maintenace and replace the parts.

- The nozzles are welded on the barrel casing, it possible to lcated in any construction.

- Optional shaft sealing for single seal mecanical seal, double mechanical seal, cartridge mechanical seal.

- Standard design for stuffing box cooling jacket allow the pump to transfer high temperaure liquid.

- Bearing bracket with cooling jacket or finned shape cooled by fan to ensure long bearing life and stable pump working.

- Bearing lubrication is optional for grease, ring oiled, splashed systems or pressuriszed systems.

- Bearing type can be rolling element bearng and sleeve bearing.

- Complete stropes are machined already for your complete monitor system to the pump.

Main benefits

- Optimum hydraulics optimized by CFD analysis and the fluid experts from Hankia Pump

- Low NPSHr and high efficiency.

- 3D design to ensure nice performance and excellent construction.

- Many choices for material, cast iron, cast steel, all stainless steel and duplex stainless steel, bronze for your different application.

- Wind performance range allow you to have a reasonable project design

- Excellent pumps with fast delivery.

- Absolutely dynamically balanced rotor prolong the lifetime and supply stable performance.

- Heavy duty service design allow the pump meet your complicated service condition.

Main application

- High pressure water feeding

- Boiling water feeding and transferring

- Water system presssure boosting

- Mining industry

- Power station and water plant

- Offshore projects

- Pertroleum oil and chemical liquid transferring

- All other application for high pressure liquid

Basic service data

- Capacityup to 450L/s (1630m3h), or as per any request.

- Headup to 2300m(7550ft), or as per any request.

- Working temperatureup to 260°C

- Design pressure4.0Mpa/6.3Mpa/10.0Mpa/16Mpa/25Mpa or as per any request.

- Nozzleup to 400mm or tailor design. Flange standard can be DIN, ANSI or other standard.