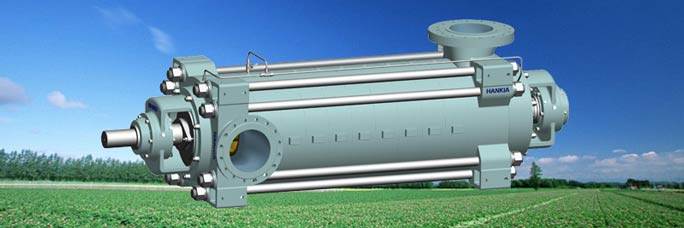

Multistage ring section pump

Pump category

Pump selection tips

All multistage pumps mentioned here are ring section pumps with redially split case. When we say multistage pump, we usually mean the multistage ring section pump although we have multistage axially split case pump. The engineers from some countries may dirrectly call it ring section pumps. We have to clarify it here in order to avoid misunderstanding. These multistage pumps are designed according to ISO standard and API610 standand.

HM type is the basic multistage ring section pumps that is the most common multitage pump that is used for clean water at different temperature. Now, we have the new generation HM multistage pump. The new generation HM multistage ring section pump has nice feature, optimizde performance, flexible nozzle orientation, etc.. It must be the best multistage pump at world class design and quality.

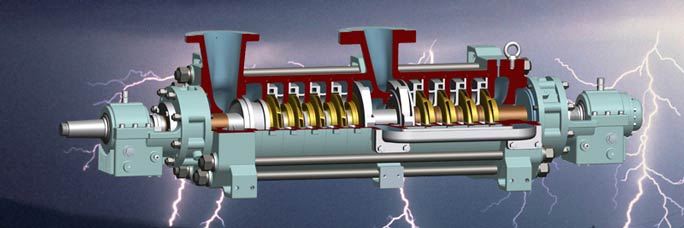

HMB multistage ring section pump and HMC multistage ring section pump are in compliance with API610 standard. HMB multistage pump have the back-to-back stacked impellers to automatically balance the axial hydraulic thrust. HMC multistage pump has similar working principal with HM type multistage ring section pump, but HMC multistage is designed according to API610 standard BB4 type. Untill now, we wish you have rouch idea about the difference between the four types of multistge ring section pump.

VM type vertical multistage ring section pump

VM type is the vertical multistage ring section pumps. The impellers are stacked in single direction on the same pump shaft. The rotor is balanced by the specially designed balance drum device. The VM multistage pump has vertical construction and compacted design, it can save your construction squares. VM type vertical multistage ring section pump is the multistage pumps for your high pressure application in the building or other sections.

VM type is the vertical multistage ring section pumps. The impellers are stacked in single direction on the same pump shaft. The rotor is balanced by the specially designed balance drum device. The VM multistage pump has vertical construction and compacted design, it can save your construction squares. VM type vertical multistage ring section pump is the multistage pumps for your high pressure application in the building or other sections.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Vertical construction to save your construction spares.

- The suction nozzle and discharge nozzle can be any position in times of 90 degree to meet your pipeline system.

- Optional shaft sealing for single seal mecanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Optional stuffing box cooling jacket allow the pump to transfer high temperaure liquid.

- Optional Bearing bracket with cooling jacket to ensure long bearing life and stable pump working.

Main benefits

- Optimum hydraulics optimized by CFD analysis and the fluid experts from Hankia Pump

- Low NPSHr and high efficiency.

- 3D design to ensure nice performance and excellent construction.

- Many choices for material, cast iron, cast steel, all stainless steel and duplex stainless steel, bronze for your different application.

- Wind performance range allow you to have a reasonable project design

- Excellent pumps with fast delivery.

- Absolutely dynamically balanced rotor prolong the lifetime and supply stable performance.

- Large scale prodution and forever sparts supply and technical support.

Main application

- Water transferring

- Water circulation

- Fire fighting

- Water system boosting

- Mining industry

- Power station and water plant

- Offshore projects

- Buildings

Basic service data

- Capacityup to 190L/s (684m3h), or as per any request.

- Headup to 280m(920ft), or as per any request.

- Working temperatureup to 160°C

- Design pressure2.5Mpa/4.0Mpaor as per any request.

- Nozzleup to 300mm or tailor design. Flange standard can be DIN, ANSI or other standard.

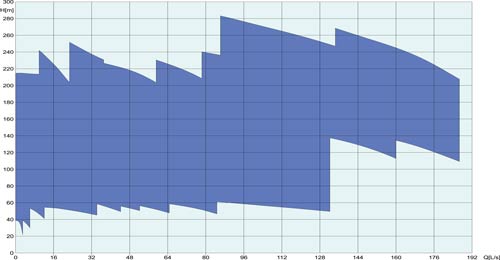

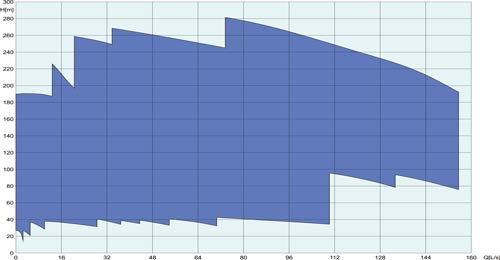

Performance range

Performance range at 50Hz

Performance range at 60Hz