Submersible & sewage pump

Pump category

Pump selection tips

Submersible pumps are the centrifugal pump designed to function with the pump and motor submerged in the fluid to lift liquid from pits, ponds, basins, wells. Submersible pumps normally handle clean or dirty water or sewage with solids.

If the submersible pump are used for submersible sewage pump. The imeller and casing designs are different from the submersible pump mainly for clean water. It is the NS type non-clog sumbersible sewage pump with special semi-open impeller. NS non-clog sewage pump can be supplied with graining teeth on the impeller to grind or chop the waste. NS sewage pump is our generation non-clog sewage pump that is absoluted the best sewage pump on the world. Sometimes it can be use as waste water pump or sewage pump to dewater the light sewage.

SSP type submersible pump are mainly for clean water or rain water or flood water.

NX type dewatering pump is suitable to as the submersible pumps in the narrow wells, pits. Because NX dewatering pump has small bore diameter and the top axial discharge. NX dewatering pump is widely used in mining, irrigation, rain water, etc..

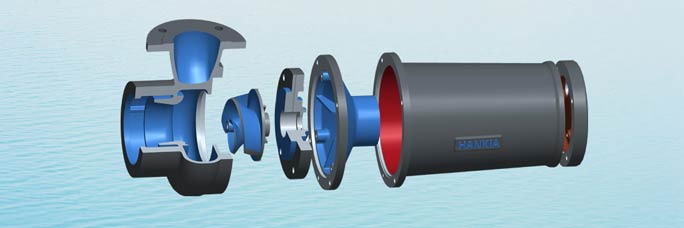

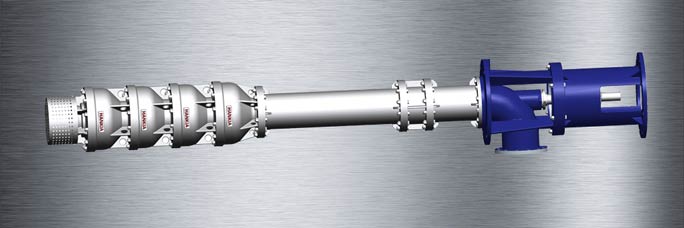

NX type dewatering pump

NX type is submersible pump and sewage pump that is mainly used as dewatering pumps in the industrial and municipal projects. The impeller can be multsitage to get high pressure. The dishcage port can be flanged type or screw type or fix by collar clutch. Portable installation allow the pumps to be installed freely. The water pumped pass through the channle between outline casing and motor stator casing, so the motor is cooled automatically and the dry installation is allowed. NX dewatering pump is widely applied in the world due to the good quality and competitive prices.

NX type is submersible pump and sewage pump that is mainly used as dewatering pumps in the industrial and municipal projects. The impeller can be multsitage to get high pressure. The dishcage port can be flanged type or screw type or fix by collar clutch. Portable installation allow the pumps to be installed freely. The water pumped pass through the channle between outline casing and motor stator casing, so the motor is cooled automatically and the dry installation is allowed. NX dewatering pump is widely applied in the world due to the good quality and competitive prices.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- The dishcage port can be flanged type or screw type or fix by collar clutch.

- The water pumped pass through the channle between outline casing and motor stator casing, so the motor is cooled automatically and the dry installation is allowed

- Down suction and up discharge.

- Stainless steel strainer control the solids into the pump.

- Complete monitor system allow you to operate the pump without any concerns.

- Single stage or multistage construction.

Main benefits

- Advance and modular design with fine production that is supplied by Hankia Pump.

- Relaible sealing.

- Wet installation or dry installation.

- Many choices for material, cast iron, hart steel, high chrome cast iron.

- Stable performance and tailor made service.

- Long lifetime.

Main application

- Drainage of rain water, flood, waste water

- Dewatering

- Irrigation or fire fighting

- Municipal projects.

- Mining industry.

- Raw water intake from river or deep well.

Basic service data

- Capacityup to 56L/s (200m3h), or as per tailor-made.

- Headup to 210m(690ft), or as per tailer made.

- Working temperatureup to 60°C

- Design pressure1.0Mpa / 1.6Mpa / 2.5Mpa

- Nozzleup to 100mm or tailor design. Flange standard can be DIN, ANSI or other standard.