Submersible & sewage pump

Pump category

Pump selection tips

Submersible pumps are the centrifugal pump designed to function with the pump and motor submerged in the fluid to lift liquid from pits, ponds, basins, wells. Submersible pumps normally handle clean or dirty water or sewage with solids.

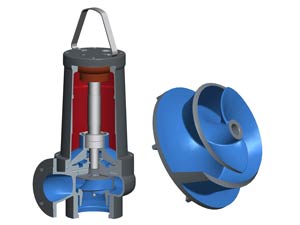

If the submersible pump are used for submersible sewage pump. The imeller and casing designs are different from the submersible pump mainly for clean water. It is the NS type non-clog sumbersible sewage pump with special semi-open impeller. NS non-clog sewage pump can be supplied with graining teeth on the impeller to grind or chop the waste. NS sewage pump is our generation non-clog sewage pump that is absoluted the best sewage pump on the world. Sometimes it can be use as waste water pump or sewage pump to dewater the light sewage.

SSP type submersible pump are mainly for clean water or rain water or flood water.

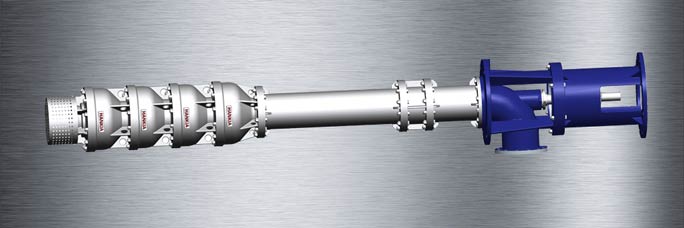

NX type dewatering pump is suitable to as the submersible pumps in the narrow wells, pits. Because NX dewatering pump has small bore diameter and the top axial discharge. NX dewatering pump is widely used in mining, irrigation, rain water, etc..

NS type non-clog submersible sewage pump

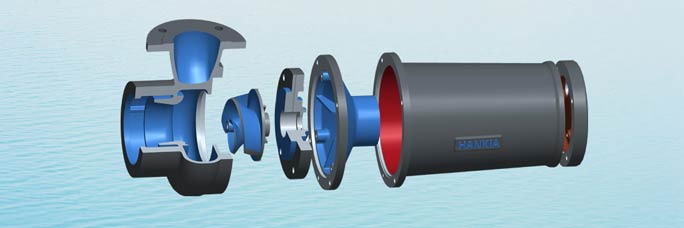

NS type is Hankia's new generation, non-clog submersible pump sewage pump and dewatering pump, that is sometimes called waster water pump. NS type non-clog submersible sewage pump has specially designed semi-open double channel impeller with unique back-sweeping angle and cleaning slot on the casing.

NS type is Hankia's new generation, non-clog submersible pump sewage pump and dewatering pump, that is sometimes called waster water pump. NS type non-clog submersible sewage pump has specially designed semi-open double channel impeller with unique back-sweeping angle and cleaning slot on the casing.

NS sewage pump can drainage the waste effectively with high effeciency, exellent reliability, and low maintenance cost. The high efficiency save the energy and reduce your operation cost at least 40% than other sewage. The pump will never overload at the total performance span. NS pumps are the best non-clog sumbersible sewage pumps and waste water pump and sewage pump used for sewage drainage, dewatering, flood controling, waste water, etc..

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Revolutionay hydaulic performance design make the pump run at high efficiency.

- Special designed cleaning slot can release the solids and strips immediately.

- The special back angle of the impeller can thrust the solids or strips torwards the out profile of the impeller and easy to be pumped out.

- High efficiency submersible squirrel cage save the power consumption.

- Optional cooling jacket allow the pump to be suitable for dry installation.

- Complete monitor system allow you to operate the pump without any concerns.

- The optional choper can cut the strips into chips effectively.

Main benefits

- Advance and modular design with fine production that is supplied by Hankia Pump.

- High effiency in long service time.

- Maintenace freely or less maintenance.

- Many choices for material, cast iron, hart steel, high chrome cast iron, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Ultra anti-cloging ability against solids and fabric strips.

- Long lifetime.

Main application

- Drainage of rain water, flood, waste water

- Slurry water

- Raw water intake

- Dewatering

- Irrigation or fire fighting

- Municipal projects.

- Offshore projects and sea water transferring.

- Power station and nuclear industry

Basic service data

- Capacityup to 3000L/s (11000m3h), or as per tailor-made.

- Headup to 70m(230ft), or as per tailer made.

- Working temperatureup to 60°C

- Design pressure1.0Mpa

- Nozzleup to 700mm or tailor design. Flange standard can be DIN, ANSI or other standard.