Single stage centrigual pump

Pump category

Pump selection tips

The single stage centrifugal pump mentioned here contain the end suction pump, close-coupled pump, inline pump. All of those pump's impeller overhungs on one end of the shaft, so they belongs to the group of overhung pumps.

The end suction pump is the most common centrifugal pump used in projects. We have IES end suction pump, NO end suction pump and NE end suction pump. Each type end suction has its own application. IES end suction pump is for general application. NO end suction pump has open or semi-open impeller are used for liquid with solids or high viscosity. NE end suction pump has inducer impeller to meet the application with low NPSH.

Another big group of pumps are close-coupled pumps. IEC close-coupled pump are derivated from IES end suction pump and have the save peformance with IES. ES colse-coupled pump are the different type of close-coupled pump usually used of 50Hz electricity.

The third group of the veritcal single stage pump are inline pump, we have IEV inline pump and ESV inline pump. IEV inline pump are also derivated from IES end suction pump and have the same performance with IEC close-coupled pump. ESV inline pump has the same performance with ES close-coupled pump.

So we suggested, if you need overhung pump, please consider firstly IES for end suction pump or IEC for close coupled pump and IEV for inline pump. because IE family pump can be used both for 50Hz and 60Hz electricity.

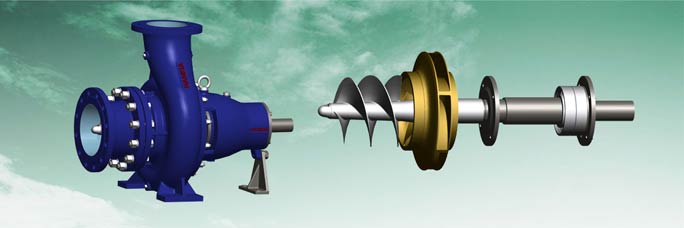

NE type single stage end suction pump

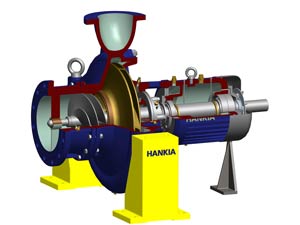

NE type is the single stage, horizontal end suction pump with closed impeller that is tailor made to your special projects. NE type end suction pump can be supplied according to both API standards and ISO 2858 and ISO5199 standards. The NE type end suction pumps are designed for heavy duty survice that request low NPSHr and high temperaure. The inducer impeller in front of the main impeller are the standard configuration for all NE type end suction pumps. The special inducer impeller definitely improve the efficiency can not be chieved by normal main impeller.

NE type is the single stage, horizontal end suction pump with closed impeller that is tailor made to your special projects. NE type end suction pump can be supplied according to both API standards and ISO 2858 and ISO5199 standards. The NE type end suction pumps are designed for heavy duty survice that request low NPSHr and high temperaure. The inducer impeller in front of the main impeller are the standard configuration for all NE type end suction pumps. The special inducer impeller definitely improve the efficiency can not be chieved by normal main impeller.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Specical optimized inducer impeller prior to the main impeller siganificantly improve the NPSH of the pump.

- Centerline support is the standard construction, it is also can be foot support.

- The stuffing box complete in complance to API 682 descriptions

- The shaft sealing is optional for single seal mecanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Optional stuffing box cooling jacket allow the pump to transfer high temperaure liquid.

- Standard finned bearing bracket can be cooled by fan to ensure long bearing life and stable pump working. If neccessary the cooling jacket can be supplied on both the fron bearing and rear bearings.

- Heavy duty bearing design is ring oiled.

- Complete stropes are machined already for your complete monitor system to the pump.

- The suction and discharge nozzle meet ISO2858 standars or according user's application.

- Heavy duty service design, the shaft can absord the huge and unstable torque.

Main benefits

- Advance and modular design with fine production that is supplied by Hankia Pump.

- Suitable for complicated and special service duty.

- Complete technical support and project consulting.

- Comparently high efficiency as compared with similar products in the market.

- Many choices for material, cast iron, high chrome cast steel, hard cast steel, all stainless steel and duplex stainless steel, bronze for your different application.

- Wind performance range and optional tailor-made design service to allow you to have a reasonable project design.

- Excellent pumps with fast delivery.

- Long lifetime and easy mentenance.

Main application

- Boiling water or other low viscosity high temperature liquid, etc.

- Considrate pumps in the power station.

- Service requesting low NPSH.

- Water circulation.

- Water injecting or boosting

- Chemical plants and oil industries.

- Petrochemical plants and nuclear industry.

Basic service data

- Capacityup to 500L/s (1800m3h), or as per tailor-made.

- Headup to 300m(530ft), or as per tailer made.

- Working temperatureup to 260°C

- Design pressure1.6Mpa / 2.5Mpa / 5.0Mpa.

- Nozzleup to 400mm or tailor design. Flange standard can be DIN, ANSI or other standard.

Performance range

Please inquiry Hankia Pump's office or agents at your local markets.

Hankia Pump Co., Limited

ADD: No. 537, Yaoxin Road, Fengxian, Shanghai, 201415, P.R.China

Tel: 86-21-67270555, 60410149 Fax: 86-21-61264327

E-mail: mail@hankia-pump.com URL: www.hankia-pump.com

Official Blog | Site map | Copyright© Hankia Pump Co., Limited All rights reserved