Single stage centrigual pump

- IES type single stage end suction pump

- NO type single stage end suction pump

- NE type single stage end suction pump

- IEC type single stage close-coupled pump

- IEV type single stage vertical inline centrifugal pump

- ES type single stage close-coupled pump

- ESV type single stage vertical inline centrifugal pump

Pump category

Pump selection tips

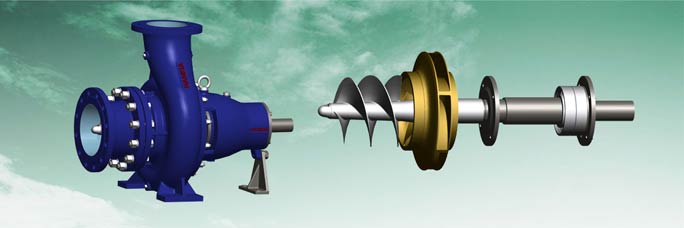

The single stage centrifugal pump mentioned here contain the end suction pump, close-coupled pump, inline pump. All of those pump's impeller overhungs on one end of the shaft, so they belongs to the group of overhung pumps.

The end suction pump is the most common centrifugal pump used in projects. We have IES end suction pump, NO end suction pump and NE end suction pump. Each type end suction has its own application. IES end suction pump is for general application. NO end suction pump has open or semi-open impeller are used for liquid with solids or high viscosity. NE end suction pump has inducer impeller to meet the application with low NPSH.

Another big group of pumps are close-coupled pumps. IEC close-coupled pump are derivated from IES end suction pump and have the save peformance with IES. ES colse-coupled pump are the different type of close-coupled pump usually used of 50Hz electricity.

The third group of the veritcal single stage pump are inline pump, we have IEV inline pump and ESV inline pump. IEV inline pump are also derivated from IES end suction pump and have the same performance with IEC close-coupled pump. ESV inline pump has the same performance with ES close-coupled pump.

So we suggested, if you need overhung pump, please consider firstly IES for end suction pump or IEC for close coupled pump and IEV for inline pump. because IE family pump can be used both for 50Hz and 60Hz electricity.

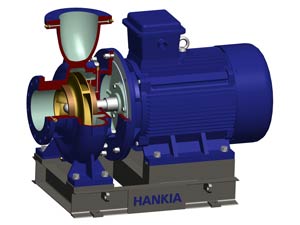

ES type single stage close-coupled pump

ES type is the single stage, horizontal close-coupled pump that is sometimes called as monoblock pump by some users.. The ES horizontal close-coupled pump share the same shaft with the standard motor. The pump and the motor is also can be coupled together through the sleeve or coupling clutch. So ES type close-coupled pump is not neccessary to verify the coaxial position and easy to maintenance. The pump and the motor is fixed direclty together through coupling bracket, then the comlete set installed on the common baseframe.

ES type is the single stage, horizontal close-coupled pump that is sometimes called as monoblock pump by some users.. The ES horizontal close-coupled pump share the same shaft with the standard motor. The pump and the motor is also can be coupled together through the sleeve or coupling clutch. So ES type close-coupled pump is not neccessary to verify the coaxial position and easy to maintenance. The pump and the motor is fixed direclty together through coupling bracket, then the comlete set installed on the common baseframe.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Double wear rings to protect pump case from friction.

- Modular design reduce the number of sizes of the spare parts to allow manage the spare parts easily.

- Pump and motor close-coupled with compacted consrutction.

- Standard configuration with single seal elastomer bellows type mechanical seal, easy to maintenance and replacement.

Main benefits

- Simple structure to save your maintenance cost and project budget.

- Suitable for standard motors, so it is easy to interchange the motor.

- Easy to replace the impeller, wear ring, mechanial seal without dimantling the motor and pipeline.

- large-scale production to ensure economic cost and easy spare parts supply.

- Improved efficiency.

- Many choices for material, cast iron, cast steel, all stainless steel and duplex stainless steel, bronze for your different application.

- Wind performance range and optional tailor-made design service to allow you to have a reasonable project design.

- Excellent pumps with fast delivery.

- Long lifetime and easy mentenance.

Main application

- Water lift and transporation in water plant and municipal projects.

- Agricultural Irrigation.

- Power station, hospitcal, buildings

- Offshore Projects and sea water.

- Air-conditioning and heating.

- Water boosting.

- Fire fighting.

- Water circation.

Basic service data

- Capacityup to 740L/s (2664m3h), if you need special performance,Hankia Pump can offer tailor made pumps for your application

- Headup to 160m(530ft), if you need special performance,we can offer tailor made pumps for your application

- Working temperatureup to 80°C

- Design pressure1.6Mpa.

- Nozzleup to 500mm or tailor design. Flange standard can be DIN, ANSI or other standard.

Performance range

Performance range at 50Hz

-50Hz.jpg)