Self-priming pump

Pump category

Pump selection tips

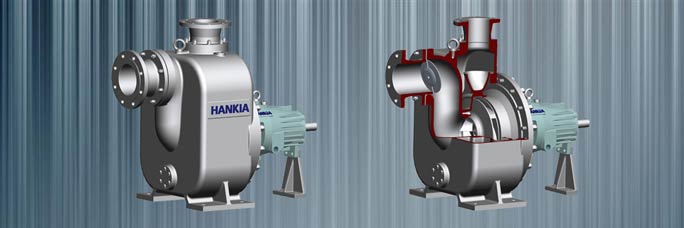

The self-priming pumps talked here belongs to the group of end suction pump. The special design of the self-priming pump casing collect a quantity of liquid to remains in the bottom of the casing. So it is not neccessary to use a vacuum pump to vent the air before starting the pump after being shut down.

According the liquid type and application fields, we have general self-priming pump mainly for clean water, it is SLF general self-priming pump. Another main type is chemical self-priming pump designed according to ISO5199 and API160 standard, it is our SP type chemical self-priming pump.

Self-priming pumps are used anywhere that a pump is running with a suction lift and not convient to have external priming device and usually the suction lift heigh is less than 6 meters (20feets).

SP type chemical self-priming pump

SP type is the single stage, end suction chemical self-priming pump with back-pull-out construction which is in compliance with ISO5199, API610. SP type chemical self-priming pumps have good suction lift head, the maximum suction head can be up to 6m. The SP type chemical self-priming pumps are usually applied in transferring corrosive luquid, like vitriol, nitric acid, sea water, sulfur liquid, etc. .SP chemical self-priming pump is your ideal option for chemical controlling and automatic process.

SP type is the single stage, end suction chemical self-priming pump with back-pull-out construction which is in compliance with ISO5199, API610. SP type chemical self-priming pumps have good suction lift head, the maximum suction head can be up to 6m. The SP type chemical self-priming pumps are usually applied in transferring corrosive luquid, like vitriol, nitric acid, sea water, sulfur liquid, etc. .SP chemical self-priming pump is your ideal option for chemical controlling and automatic process.

Main designing features

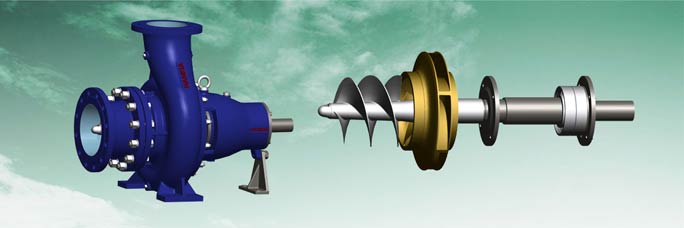

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Optimized impeller has high efficiency.

- Back-pull-out construction is easy to maintenance and replacing the spare parts.

- The shaft sealing is optional for single seal mecanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Standard stuffing box cooling jacket integrated inside the casing cover allows the pump to transfer high temperaure liquid.

- Standard finned bearing bracket or bracket with cooling jacket to ensure long bearing life and stable pump working.

- Heavy duty bearing design is ring oiled.

- Complete stropes are machined already for your complete monitor system to the pump.

- The suction and discharge nozzle meet ISO2858 standars or according user's application.

- Heavy duty service design, the shaft can absord the huge and unstable torque.

Main benefits

- Advance and modular design with fine production that is supplied by Hankia Pump.

- Good quality with competitive prices

- Comparently high efficiency as compared with similar products in the market.

- Many choices for material, cast steel, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Excellent pumps with fast delivery.

- Long lifetime and easy mentenance.

Main application

- Chemical plants.

- Petroleum products transfering.

- Paper and pulp industry.

- Oil and chemical loading on ships or at sea port.

- Sugar and berry industry.

- Offshore projects and sea water transferring.

- Power station and nuclear industry

Basic service data

- Capacityup to 111L/s (400m3h), or as per tailor-made.

- Headup to 125m(410ft), or as per tailer made.

- Working temperatureup to 240°C

- Design pressure1.6Mpa

- Nozzleup to 200mm or tailor design. Flange standard can be DIN, ANSI or other standard.

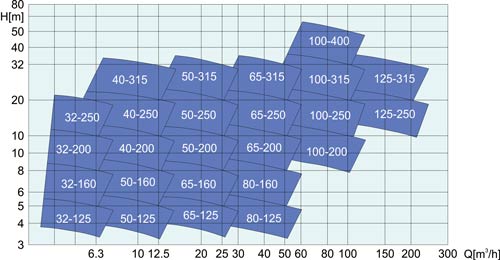

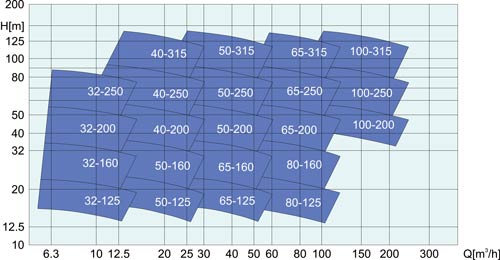

Performance range

Performance range at 2900r/min

Performance range at 1450r/min