Petroleum chemcial pump

Pump category

Pump selection tips

The petroleum chemical pump always focus on the reliablity because the petroleum chemical pump are usually used for corrosive liquid with high temperature and operate in dangerous condition. Hankia's have various petroleum chemical pumps according to ISO13709, API610, ISO5199 and ISO2858 by considering the application condition and project budget.

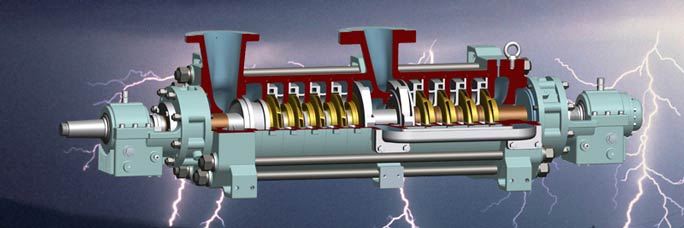

The have duty service petroleum chemical pump are mainly refer to the standard ISO13709 and API610. Those pumps are CA OH1 petroleum chemical pump, CC OH2 petroleum chemical pump and CO petroleum chemical pump. CO type with open or semi-open impeller can be OH1 and OH2 construction.

HZ chemical pump and CH chemical pump are designed according to ISO2858 to the general application of chemical liquid or chemical process controling. CH chemical pump are designed with pressure 1.6Mpa and HZ chemical are designed with 2.5Mpa as the standard configuration.

For the chemical controlling or automatic process, we have SP type self-priming chemical pump in compliance with ISO5199 and API610.

So you can find the right chemical pumps in our product range.

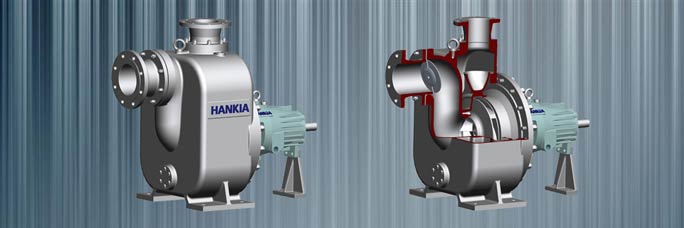

HZ type standard chemical process pump

HZ type is the single stage, end suction standard chemical process centrifugal pump in compliance with DIN24256 and ISO2858. The HZ type end suction chemical pumps are designed with double volute casing to balance the radial force and can work with high pressure. Back-pull-out design allow you to repair the pump without dismantling the pipelines. HZ type end suction chemical pump can be used to transfer corrosive liquid and petroleum liquid at differenct temperature.

HZ type is the single stage, end suction standard chemical process centrifugal pump in compliance with DIN24256 and ISO2858. The HZ type end suction chemical pumps are designed with double volute casing to balance the radial force and can work with high pressure. Back-pull-out design allow you to repair the pump without dismantling the pipelines. HZ type end suction chemical pump can be used to transfer corrosive liquid and petroleum liquid at differenct temperature.

Main designing features

- 3D design used in the whole design process and CFD analysis and being embodied with knowledge and experience of the fluid experts in Hankia Pump.

- Specical optimized impeller with high efficiency and heavy duty service.

- Double volute casing balance the radail force to rotor.

- Optional inducer impeller can be supplied to improve the NPSH.

- The stuffing box complete in complance to API 682 descriptions

- The shaft sealing is optional for single seal mecanical seal, double mechanical seal, cartridge mechanical seal and soft packing.

- Standard stuffing box cooling jacket allow the pump to transfer high temperaure liquid.

- Standard finned bearing bracket or bracket with cooling jacket to ensure long bearing life and stable pump working.

- Heavy duty bearing design is ring oiled.

- Complete stropes are machined already for your complete monitor system to the pump.

- The suction and discharge nozzle meet ISO2858 standars or according user's application.

- Heavy duty service design, the shaft can absord the huge and unstable torque.

Main benefits

- Advance and modular design with fine production that is supplied by Hankia Pump.

- Heavy duty design allow the pump to be qualified for complicated service.

- Stuffing box designed to be suitable for major famous mechanical seal brands, so you can replace the seal easily.

- Comparently high efficiency as compared with similar products in the market.

- Many choices for material, cast steel, all kinds of stainless steel, duplex stainless steel and steel alloy.

- Wind performance range and optional tailor-made design service to allow you to have a reasonable project design.

- Excellent pumps with fast delivery.

- Long lifetime and easy mentenance.

Main application

- Petroleum and chemical plants.

- Paper and pulp industry.

- Sugar and berry industry.

- Offshore projects and sea water transferring.

- Power station and nuclear industry

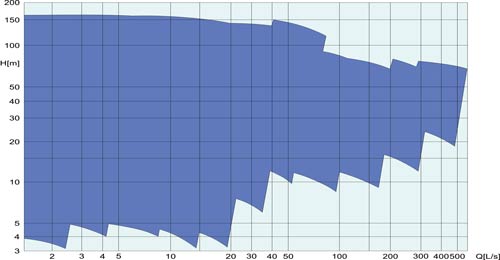

Basic service data

- Capacityup to 556L/s (2000m3h), or as per tailor-made.

- Headup to 160m(525ft), or as per tailer made.

- Working temperatureup to 300°C

- Design pressure2.5Mpa / 5.0Mpa.

- Nozzleup to 400mm or tailor design. Flange standard can be DIN, ANSI or other standard.

Performance range